There are many Health and Safety Consultants out there, so why choose DanumBS?

Managing health and safety in your business is not only a legal requirement, it’s the right thing to do to protect your people, assets, reputation and finances. Working with the right consultant, who takes time to know and understand your business, can help you protect your people and business easily and effectively.

Why work with a Health and Safety Consultant?

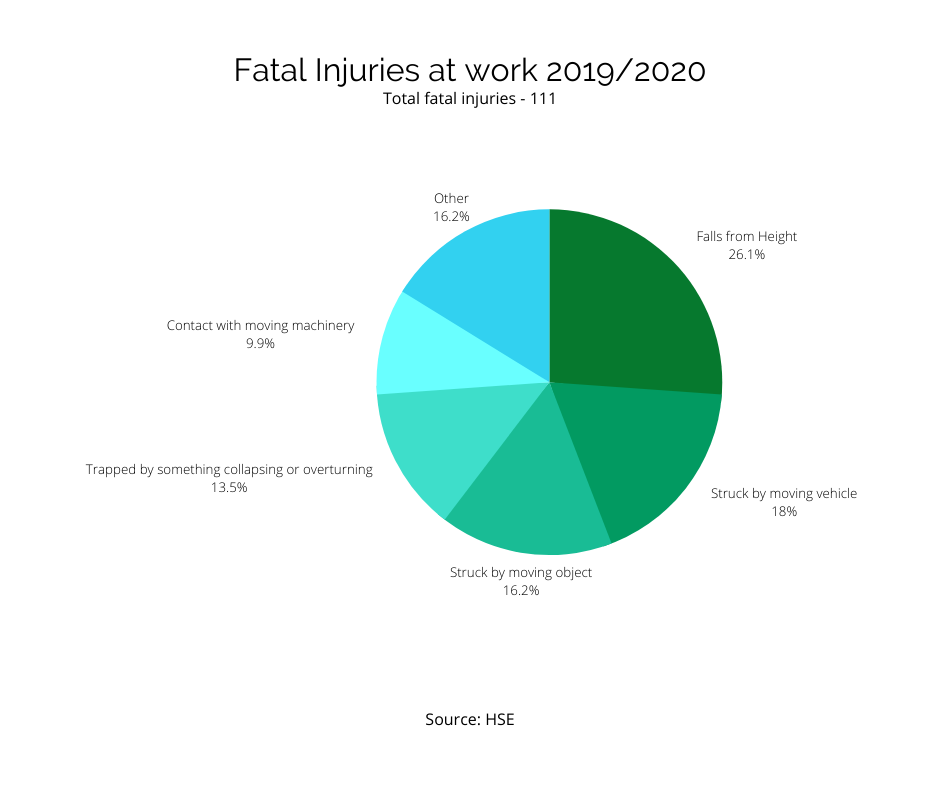

Have you had a look at the HSE website recently? There is a tonne of useful information and guidance on there to help businesses of all sizes to manage health and safety successfully in their organisation. If you have the time to deep dive into the website, you can find everything you need to meet your legal requirements.

But how do you know what you need? Can you be sure you have covered all the bases? And do you have time to sit and digest loads of guidance to find the nugget of information you need?

It is a legal requirement for every employer to appoint a competent person to assist them with their health and safety undertakings. This doesn’t automatically mean that you must use an external H&S Consultant, but if somebody within your organisation is appointed as your competent person you need to ensure they have enough time to carry out their H&S duties, and that the person(s) have the right skills, knowledge, attitude, training, and experience to meet the needs of the business.

Many SME’s will not have the need to appoint a full-time health and safety employee, or anyone within the organisation with the right knowledge and experience to meet the businesses H&S needs as well as fulfil their own job-role.

Working with a H&S Consultant brings you the expertise you need, when you need it, with the added value of getting access to somebody who works across a number of businesses and sectors. This means you get the benefit of your H&S Consultant learning and knowing what works well for different organisations.

Why choose DanumBS for health and safety support?

Here at DanumBS you get me – Tracy – and I believe that Health and Safety is not your number one focus or priority in your business. For me, health and safety is a value. Much like honesty, simplicity, and reliability. Its non-negotiable, and part of everything I do.

The reason for this? Areas of focus and priorities change, depending on what is going on in the business on any given day. Values are embedded, while priorities can change.

When working with me you get those same values brought into the heart of your business. My job is to give you the clear advice and support you need to enable to go about your day-to-day work, knowing you are doing all you need to do to keep people safe.

I’ve worked around H&S all my career. I started off working at a large consultancy as a Chemical Engineer designing safety systems for chemical plants to make sure they didn’t go bang. I then worked as a Quality, Health, Safety and Environmental Advisor for the same Consultancy (with the longest job title I’ve ever had). This is where I fell love with the idea of putting management systems, procedures and steps in place that are meaningful and easy to use on a day-to-day basis. There is no point in writing risk assessments, procedures, etc if they are overly complicated and never going to be followed in ‘real life’. You don’t get death by clipboard and red-tape with me! I moved from the Consultancy role to work on a chemical manufacturing site. In this job I had both process safety and occupational health and safety to look after. From meeting regulatory requirements, emergency planning, daily H&S matters, projects to improve standards, working with site staff and contractors, and looking after a construction project on a live chemical plant this was a job with a huge scope and a great experience. Now I have my own H&S Consultancy, DanumBS, where I get to work with some brilliant clients of all sizes in all kinds of industries (from Covid testing labs, medical charities, woodworking factory and telecoms to name a few!).

Why am I telling you all this? So you know that I understand what it’s like to be in your shoes. Businesses have all kinds of competing pressures, you have to meet the demands of your customers, keep your people happy, earn enough money to be financially viable and many other things besides. You want to make sure you are keeping your people safe and protecting your business in a way that is integrated into everything you do, so that that safety is ‘baked-in’ to all of your activities and processes and in a simple, cost-effective way. I can help you achieve that, giving you peace of mind and a happy, healthy workplace.

Whether I am working with you on a specific project, for example developing your risk assessments, or working with you on a longer term basis as your appointed Competent Person (check out my Safe Business Solution tailored for your business) you get the same approach from me. I love to take time to build up a great working relationship with clients, to really understand their business and their culture, and to find out who makes the best coffee!

When you choose DanumBS as your trusted health and safety partner, you know you will get top-notch technical advice delivered in an understandable and easy to implement way,

Want to have a chat and start getting to know each other?

![100mm x 100mm Wear Safety Boots Sign [Sticker Self Adhesive Vinyl] Workshop Office Personal Protection Safety: Amazon.co.uk: Kitchen & Home](https://images-na.ssl-images-amazon.com/images/I/419JPwLQVgL._AC_SX466_.jpg)