Do you understand what PPE is, how to choose the correct type, who is responsible for it and how to look after it?

PPE, or Personal Protective Equipment, is used across most industries and settings. PPE is our last line of defence against hazards, so it is important that it is selected, used and maintained correctly.

There are a specific set of regulations that cover the use of PPE, these are the Personal Protective Equipment at Work Regulations.

What is PPE?

Personal Protective Equipment is exactly what it says – it is equipment designed to be worn or used on the person to protect them from specific hazards.

While PPE can be vital in keeping people safe, it shouldn’t be the only thing we consider as a protection measure. A big failing of PPE is that it protects only one person, not many, and it is open to misuse or disrepair which will have an impact on any protection factor.

As you are assessing risks and looking at ways to control hazards, relying on PPE should be your last choice of control. You must first try to eliminate the hazards, use engineering controls and put a safe system of work in place to minimise the risks. Only once you have gone as far as you can with these controls, can you start considering the use of PPE to protect the individual.

Most of us have used PPE in some form or another, if only by wearing a pair of marigolds when doing the washing up to stop the skin on our hands drying out. The table below shows the most common types of PPE and the hazards they offer protection against.

Common types of PPE

| Type | Example hazards it offers protection against | ||

|---|---|---|---|

|

Head Protection |  |

Safety Helmets Bump Caps Firefighters Helmets |

Impact on low level / head height objects Falling plant or equipment from lifting operations, conveyors, machinery, elevated work places (e.g. scaffold) Falling branches from tree felling Flying debris from blasting operations |

|

Eye & Face Protection |  |

Safety Specs Goggle Full-face Visors |

Liquid or chemical splashes Chippings or dust from use of power tools Dust, gas, liquid or mist formed during cleaning operations Intense light or radiation, e.g. welding |

|

Hand & Arm Protection |  |

Gloves Gauntlets Sleeving / Arm Protection |

Cuts and abrasions from rough or sharp surfaces and edges Contact with chemicals (note gloves need to be rated for the specific chemical hazard you are protecting against) Keep hands warm when operating machinery that causes vibration Extreme hot or cold temperatures / materials Radioactive materials Electrical hazards |

|

Foot Protection | ![100mm x 100mm Wear Safety Boots Sign [Sticker Self Adhesive Vinyl] Workshop Office Personal Protection Safety: Amazon.co.uk: Kitchen & Home](https://images-na.ssl-images-amazon.com/images/I/419JPwLQVgL._AC_SX466_.jpg) |

Safety Boots or Shoes Wellingtons |

Crush injuries from object falling on feet or toes Extreme cold environments Electrical hazards Chemical spills (boots must be rated for specific chemical hazard you are protecting against) Explosion risk – antistatic footwear used in potentially explosive atmosphere Wet environments when using water sprays |

|

Hi-Vis Clothing |  |

Waistcoats Jackets Trousers Coveralls |

Hazard is person not being seen in the work environment that may lead to collision or trapping injury.

Typical places hi-vis is worn are:

|

Other types include:

- Protection clothing, e.g. cut resistant chain mail apron

- Drowning protection, e.g. buoyancy aids and life jackets

- Personal fall protection, e.g. rope access systems

- Respiratory Protective Equipment (RPE), e.g. respirators and breathing apparatus

A note about hearing protection: the PPE regs do not apply to hearing protection, other than to say that any hearing protection used must be compatible with other PPE. The use of hearing protection is covered by the Control of Noise at Work Regulations.

PPE is not

- Ordinary work clothing or uniforms

- Clothing provided for food hygiene purposes

- Equipment used in competitive sports

- Bike or motorcycle helmets

- Personal radiation and gas detectors

What do you need?

The need to use PPE will typically be identified through the risk assessment process, for example from COSHH assessments, general workplace assessments, task-based assessments, etc.

Once you have identified the need for PPE, you then need to select the correct type to protect against the specific hazards. You need to also make sure that it does not increase any risks to the user, and the aim is to select PPE that gives the maximum benefit for the user while causing the minimum discomfort – uncomfortable PPE will not be used properly.

All PPE must carry a CE mark that shows it meets the requirements of the Personal Protective Equipment (PPE) Directive 89/686/EEC. PPE could carry a CE mark from other Directives, so you need to make sure that any CE mark is specifically for the PPE Directive. This information is readily available from your supplier.

When using more than one item of PPE, you must make sure that they are compatible. For example, the use of a full-face respirator that does not allow you to wear a safety helmet at the same time would not be suitable for an environment where a safety helmet is needed.

The PPE Regulations are supported by guidance L25 Guidance on the Personal Protective Equipment at Work Regulations, where further information about correct selection is given in Part 2 Selection, use and maintenance of personal protective equipment.

If you need help on selecting the right PPE, then talk to your Health and Safety Consultant or specialist suppliers who will be happy to guide you.

Who is responsible?

Employers duties

Employers are responsible for identifying PPE needs, and making sure there is a readily available supply. Most PPE is supplied on an individual basis – you would not ask people to share hard hats, boots, gloves, etc. but some items such as breathing apparatus can be shared. Where it is shared, employers must have a process in place to make sure it is properly cleaned and decontaminated between uses.

For agency workers, the site operators (eg a Construction site) might provide appropriate PPE so they know the workers are protected. In this case, the agency employing the workers does not have to provide additional PPE although they do have a duty to ensure that the it has been provided.

An employer cannot charge any employee or agency worker for the provision of PPE, nor should an employee be asked to pay a returnable deposit.

When issuing PPE you need to make sure the users know the correct way to use it. The employer is responsible for providing suitable information, instruction, and training for their people so that they can use it effectively. Training should be appropriate to the intended use of the PPE – you don’t need a day long training course on how to wear a safety helmet, but training in the use of rope access systems will take a little while!

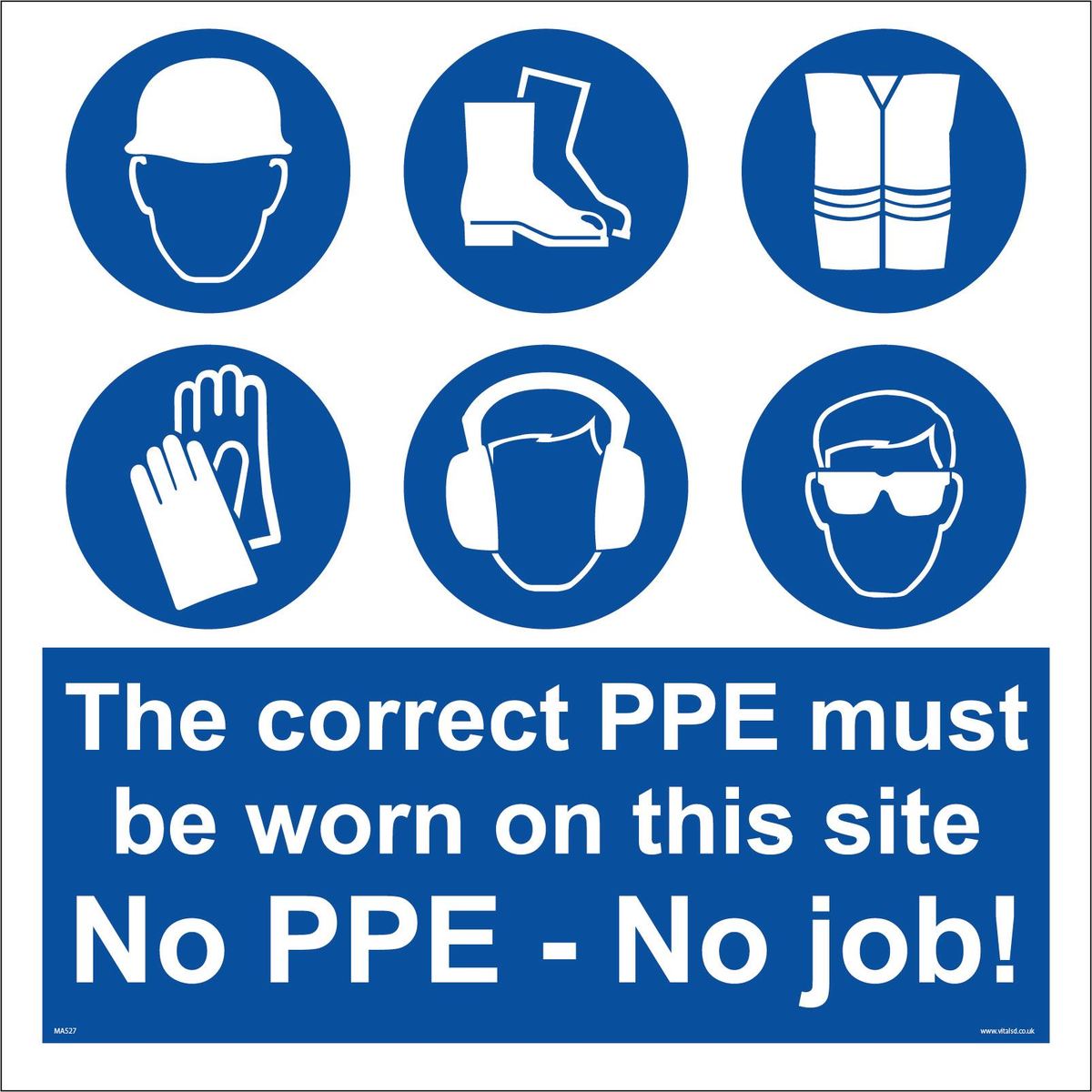

Make it clear in your workplace where PPE is needed by displaying safety signing at entry points to areas with particular hazards.

Employees duties

Employees need to take care of any PPE issued to them, and they must not use it until they have received suitable training.

PPE should be checked before each use, and any defects reported to the employer so that it can be repaired or replaced.

If employees have any concerns about the use, suitability or state of PPE they should raise their concerns immediately with their employer or any employers representative.

What do you need to do to look after PPE?

Once PPE has been issued, it needs to be looked after to make sure it continues to offer the correct level of protection. A documented system to manage PPE helps here, with records of what equipment has been issued to who, and any periodic maintenance, inspection or enquiry dates recorded and a system in place for recall of items when needed.

Your management system should include the following:

- Examination – checking for faults, damage, wear and tear, etc.

- Testing – to ensure it is operating as intended.

- Ready for use – making sure when PPE is returned it is made ready for use before being issued again.

- Cleaning arrangements – including disinfection and decontamination where necessary.

- Repair

- Replacement

You should also make suitable arrangements for the storage of PPE, taking care to store clean and dirty items (awaiting cleaning) separately to prevent any cross-contamination.

So, what is the key message to take away?

PPE is always a last line of defence against any potential hazard because it protects only the individual (not the workforce collectively) and can be subject to misuse or disrepair. You should only look to use PPE where all other hazard control measures have not reduced the risk to an acceptable level. You must be careful to select the right PPE to make sure it is protecting against the identified hazards, and it must be comfortable and easy to use. PPE only protects the individual if it is well maintained and used correctly, so make things as easy and as comfortable as possible to get the best compliance with your PPE policies.

Got any questions about PPE or need any guidance?